Our Technology

Environmental sustainability – the base of our modules

For the production of the modules, raw materials are used that are available everywhere in large quantities and at low cost. These mainly include the almost inexhaustible desert sand, lime and water. Aerated concrete is produced from these raw materials. The energy necessary for the production of our modules can be provided in suitable regions completely by solar energy and/or energy bundling plants. Thus the production is CO2-neutral and will not pollute the environment.

Sealing

During the manufacturing process, a special waterproof sealing layer is applied. The constant quality of the modules is guaranteed by the use of a process technology developed in-house. And it guarantees the longevity and low maintenance of the modules manufactured to the highest quality standards. Each individual module is floatable, robust, resistant to all current environmental influences and therefore weatherproof, no matter if single or clustered.

Resistance

This is why we particularly focused on durability, and developed a process, that makes our product unique. Because our modules are made of a stable aerated concrete and sealed through a special process, developed by us. The service life of the sealing is estimated at at least 100 years when exposed to environmental influences and the surrounding water.

But even that’s not enough for us. With high pressure we’re currently working on a sealing, which doubles or even triples this figure. This results in a resistance that was previously only available on the mainland.

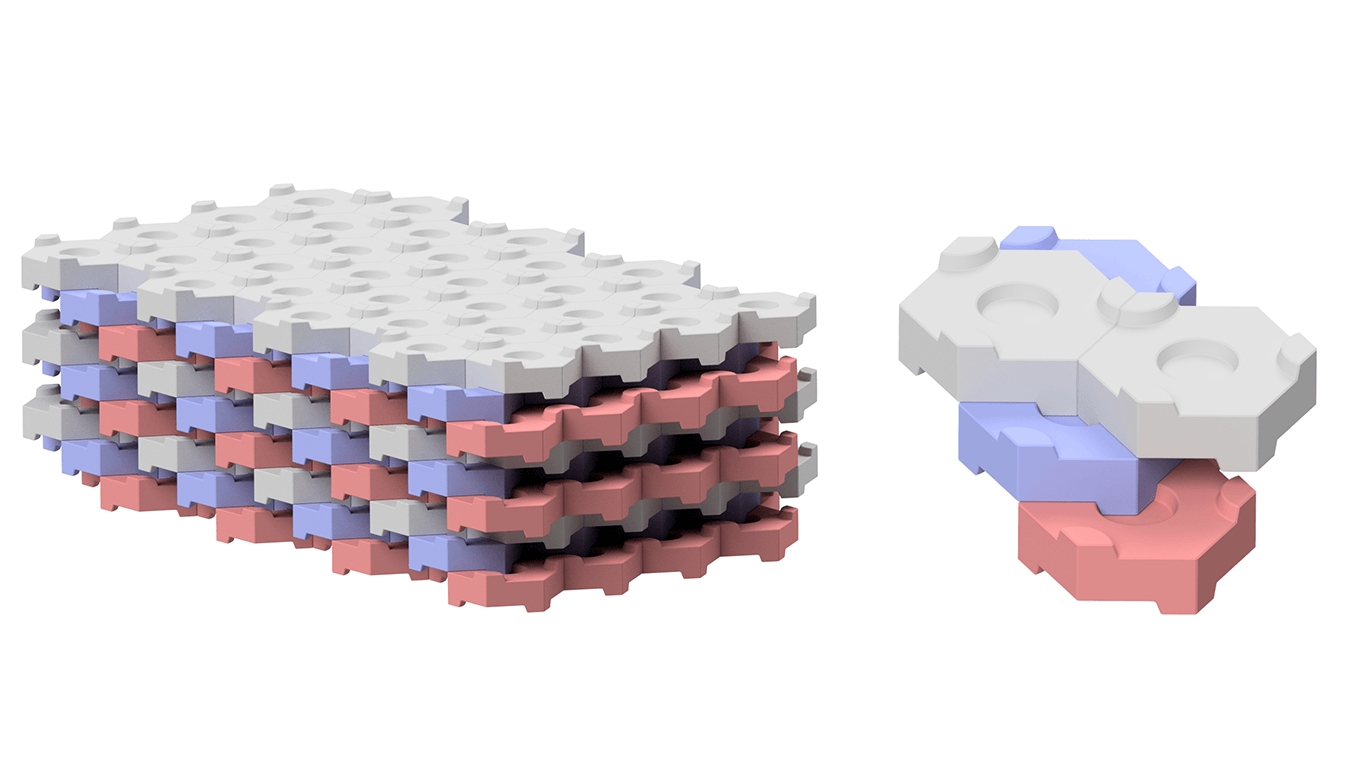

Scalability

Load Capacity

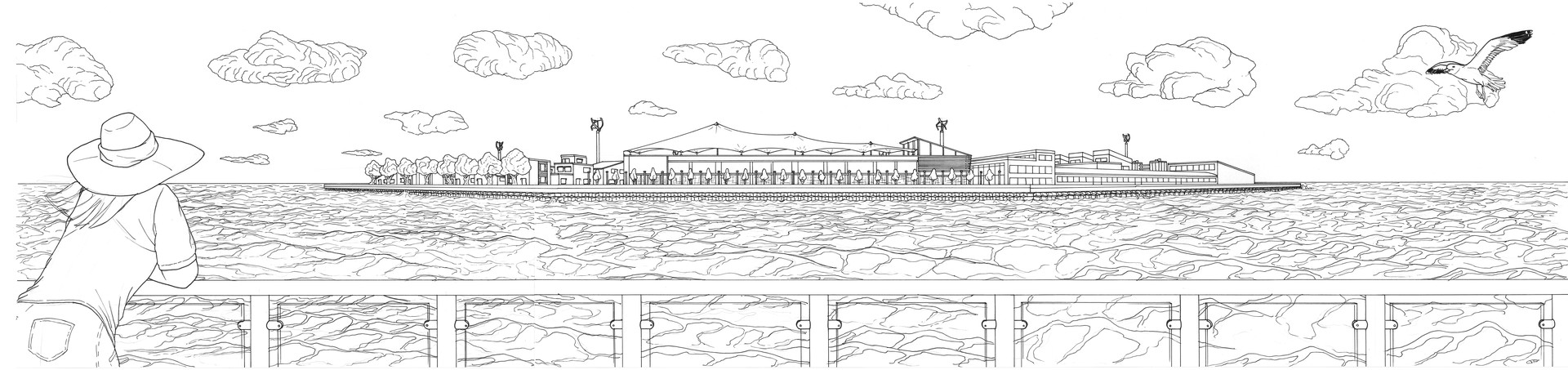

Our modules differ from every other concept on the market in one substantial aspect. Our modules and projects are free in scale and size. And always planned individually. With our system you can effortlessly design:

– platforms for a single-family house with an area of 400 sq m

– platforms for warehouses oder event islands from 2.000 sq m

– platforms for hotel complexes with an area from 60.000 to 90.000 sq m

– platforms for raw material extraction or energy generation with far more than 100.000 sq m

Only your imagination sets the limit, because the platforms load capacity can be scaled as easily as their size. And the best part of it: Already existing platforms can thus be altered even after several years of use. Even partial changes in load distribution aren’t a concern anymore. You want to change the load subsequently, because your tasks increased? Not a problem with our modules. That means:

Nothing is unthinkable and nothing is not doable!

Low costs

Our modules can be produced cost-effectively and environmentally sustainably. This is because the raw materials used to manufacture the modules are available everywhere in large quantities at low cost. These mainly include desert sand, lime and water.

Our great advantage is that the sand for aerated concrete does not require the usual grain size, because the sand is first ground to cement fineness for the production of aerated concrete. Thus, deposits, that were previously unsuitable for building construction and civil engineering are now eligible for our modules. This primarily includes the desert regions of the world. However, the sand that is available there in great quantities could not be used for construction projects. This changes with our process, and we can access a resource that will remain permanently cost effective. Limestone is also to be found in large quantities either dissolved in the water or as sediment of dead mussels on the seabed, an almost inexhaustible source. Thus, the other raw material required is also an easily obtainable and abundant. That way, the production of our modules from aerated concrete does not rely on limited or expensive raw materials – which will be reflected in a permanently favorable and sustainable production.

The process for the production of aerated concrete has been very well researched and is already practiced today by well-established companies at extremely low costs.

Unrivalled

In addition, all competing products have their two-dimensionality in common. Basically, these are always so-called pontoons, whose size and payload is fixed in advance and can no longer be adjusted during the course of the project. Only the Island City Module System uses the third dimension and enables highly complex structures that can be varied at any time. This makes us absolutely unrivalled. No one else offers such a system.

Fast assembly

In close cooperation with us, Vertical Works GmbH is developing a mega drone for the fast assembly of even the largest platforms. This mega-drone will be able to accommodate our modules, transport them in the shortest possible time to a destination up to 2 kilometers away and place them there with pinpoint accuracy. With the help of a specially developed software we will be able to install up to 100 drones at the same time.

Get our information papers now

If you like to get more information about the project, you can download our brochures here.

Patented Innovation

Our system is nationally and internationally patent pending. The Island City Module System is absolutely unique. Never before has anyone patented such a system, or anything even close to it. This paves the way for a completely new market – with patented, protected and unique modules.